The CNC machines, especially the turning centers have limitations when it comes to achieving small and highly complex shapes like watch components. However, the Swiss turning can create small and precise parts for diverse applications across industries.

Furthermore, it is essential to be updated with the Swiss turning to leverage the advantages of this technology. Therefore, we have discussed “Swiss Turnings Today” in this article.

The Swiss Turning History and Development

The history of Swiss Turning can be traced back to the late 19th century, originating in the watchmaking industry. The plot of development of necessities of precision in tiny watch components.

With time, the turning technology has spread around all the industries, from automotive to aerospace and medical. Meanwhile, Custom Online CNC Machining Services are popular for addressing the unique and custom needs of clients from anywhere in the globe.

The following table shows the major milestones in the development of Swiss-turning technology:

1890: A Swiss-type lathe for watchmaking was invented in Switzerland.

1920: Adaptation across all industries beyond watchmaking, like aerospace and defense.

1980: Introduction of CNC technology, a new era of Swiss turning precision.

2010: Precise monitoring, robotics & AI integration for process and quality control

What Materials Can Swiss Turning Process Today?

Now, let’s take a look at the innovations in the material capability of Swiss turning machines. Initially, it was mainly used to machine aluminum, copper, and steel. However, material science and CNC machining technology advancements have made it possible to shape more than 100+ materials with proper tooling.

For example, now advanced CNC Swiss turning machines can handle titanium alloys while maintaining the same level of precision as stainless steel.

The most common Swiss turning materials are; Stainless Steel, Aluminum, Brass, Copper, Titanium, Nickel Alloys, gold, silver, PEEK, ABS, and PC. These options of material are advantageous as give more choice to the manufacturer. They can select the appropriate material that exactly matches the application requirement.

What are the Quality Control Advancements in Swiss Turning Today?

The overall result of any machining process is decided by the quality of the part. So, quality control is a critical process to maintain the quality and ensure that swiss-turned parts meet all the requirements and specifications like tolerance, dimensions, surface roughness, etc. The Swiss turning machines involve advanced quality control mechanisms, like motion sensors, process monitoring, defect identification, tool wear monitoring, etc.

Moreover, large machining firms can train the control systems using AI to analyze the tool path, optimize the cycle time, predict the faults, and identify the turning defects. As a result, manufacturers can enhance precision and overall productivity.

The Precision Advancements of Swiss Turning Today

Do you how precise the Swiss turning machines are today? They can achieve tolerances as tight as ±0.0001 inches. This tolerance is enough to create precise parts for aerospace, medical, defense, and automotive applications.

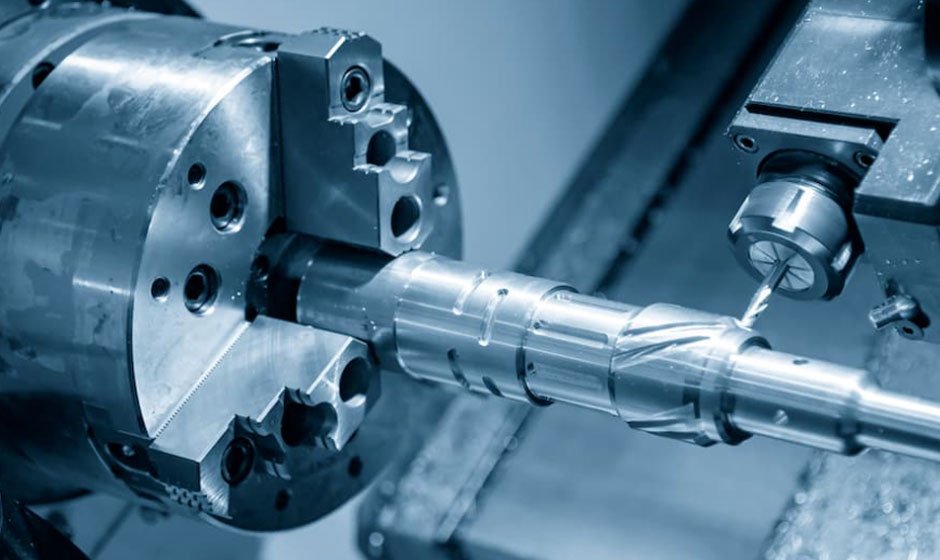

Precision CNC machining

The precision capabilities Swiss turning machines have these days have made it possible to create high-performing engineering applications like aerospace engine parts and precise applications like custom dental implants.

Summing Up

Overall, Swiss turning brings precision and quality in the machining of diverse parts and products for countless industries. However, it is essential to understand the latest capabilities and limitations of the Swiss turning machine to optimize its use in your project.