Precision and reliability are paramount in electronics and technology. Whether you’re designing circuits, troubleshooting hardware, or maintaining equipment, having the right electronic test equipment is crucial. These tools are the backbone of any engineering lab or manufacturing facility, ensuring that devices function as intended and meet quality standards. In this blog post, we’ll delve into the essential attributes that define electronic test equipment and explore why they are indispensable for professionals in the field.

Accuracy

One of the foremost attributes of electronic test equipment is accuracy. Engineers and technicians rely on these instruments to precisely measure voltage, current, resistance, frequency, and other parameters. Accuracy ensures that test results are trustworthy and can be used to make informed decisions during product development or maintenance.

Modern electronic test equipment often comes with calibration features to maintain accuracy over time. Calibration ensures that the instrument’s readings remain consistent and reliable, especially in environments where temperature and other conditions can impact performance.

Versatility

Versatility is another key attribute of electronic test equipment. Different projects and tasks require varying measurement techniques and capabilities. Versatile instruments can adapt to these demands, reducing the need for multiple specialized tools.

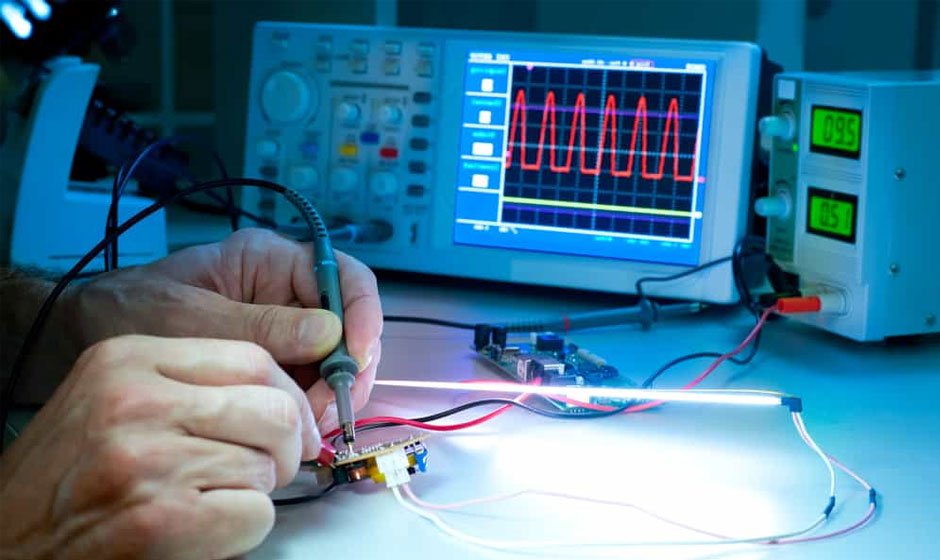

For example, a digital multimeter (DMM) is a versatile device that can measure voltage, current, resistance, and continuity. Oscilloscopes are another essential tool known for their versatility, enabling engineers to visualize electrical signals across a wide range of frequencies in real-time.

Precision

Precision goes hand in hand with accuracy but refers more specifically to the instrument’s ability to resolve small changes in measurement. High precision is vital when working with sensitive electronics or when troubleshooting intricate circuitry.

Signal generators, for instance, require precise frequency and amplitude control to simulate specific conditions accurately. Likewise, spectrum analyzers must resolve minute signal details within a spectrum to identify interference or frequency components.

Reliability

Reliability is non-negotiable in electronic test equipment. Professionals depend on these tools to function consistently under various conditions without failure. Reliability minimizes downtime and prevents costly errors during critical testing procedures.

Robust construction, quality components, and adherence to industry standards contribute to the reliability of electronic test equipment. Regular maintenance and calibration further enhance reliability, ensuring that instruments perform optimally throughout their lifespan.

Ease of Use

In today’s fast-paced engineering environments, usability is a significant factor in selecting electronic test equipment. Instruments should be intuitive to operate, with clear interfaces and ergonomic designs that enhance productivity.

Features like touchscreen displays, intuitive menus, and built-in tutorials streamline the learning curve for new users. Remote monitoring and control capabilities also contribute to ease of use, allowing professionals to access test data from anywhere within a facility.

Connectivity

The ability to interface with other devices and systems is crucial in modern electronic testing. Connectivity features enable data sharing, automation, and integration with software tools for advanced analysis.

Many electronic test instruments now support standard interfaces like USB, Ethernet, and wireless protocols for seamless connectivity. This enables real-time data logging, automated testing sequences, and remote access to test results.

Measurement Range and Resolution

Electronic test equipment should offer a wide measurement range to accommodate diverse applications. When measuring microvolts or kilovolts, instruments must maintain accuracy and resolution across their specified range.

Resolution is particularly critical when dealing with small signals or subtle measurement variations. High-resolution displays and analog-to-digital converters ensure that engineers can confidently discern minute changes.

Durability

Durable is essential given the demanding environments where electronic test equipment is often used. Instruments must withstand physical stresses, environmental factors, and frequent use without compromising performance.

Rugged enclosures, reinforced connectors, and protective features guard against accidental damage and ensure longevity. Portable instruments, such as handheld oscilloscopes and multimeters, benefit significantly from durable construction.

Safety

Last but certainly not least, safety features are indispensable in electronic test equipment. Working with electrical circuits carries inherent risks, and instruments must prioritize user safety.

Built-in protections against over-voltage, over-current, and short circuits safeguard both the equipment and the user. Safety certifications and compliance with international standards further validate the instrument’s suitability for professional use.

Cost-Effectiveness

While quality and performance are paramount, cost-effectiveness also plays a significant role in selecting electronic test equipment. Professionals seek instruments that offer the best value for their investment, balancing features with budget constraints.

Long-term reliability and minimal maintenance requirements contribute to the overall cost-effectiveness of electronic test equipment. Investing in durable, high-quality instruments can yield substantial returns by reducing downtime and ensuring accurate results over time.

Innovation and Future-Proofing

Innovation drives the evolution of electronic test equipment. Manufacturers continually introduce new features and technologies to meet the demands of emerging industries and applications.

Features like cloud connectivity, artificial intelligence, and automated test routines represent the future of electronic test equipment. Professionals who embrace innovation can future-proof their labs and stay ahead in a rapidly evolving technological landscape.

Conclusion

Electronic test equipment forms the backbone of electronics development, manufacturing, and maintenance. These tools empower engineers and technicians to validate designs, diagnose faults, and ensure quality with precision and confidence.

Electronic test equipment enables innovation and excellence in the ever-evolving field of electronics by embodying attributes such as accuracy, versatility, precision, reliability, ease of use, connectivity, measurement range, durability, safety, cost-effectiveness, and innovation.

Whether you’re a seasoned professional or an aspiring engineer, investing in quality electronic test equipment is essential for success in today’s technology-driven world.